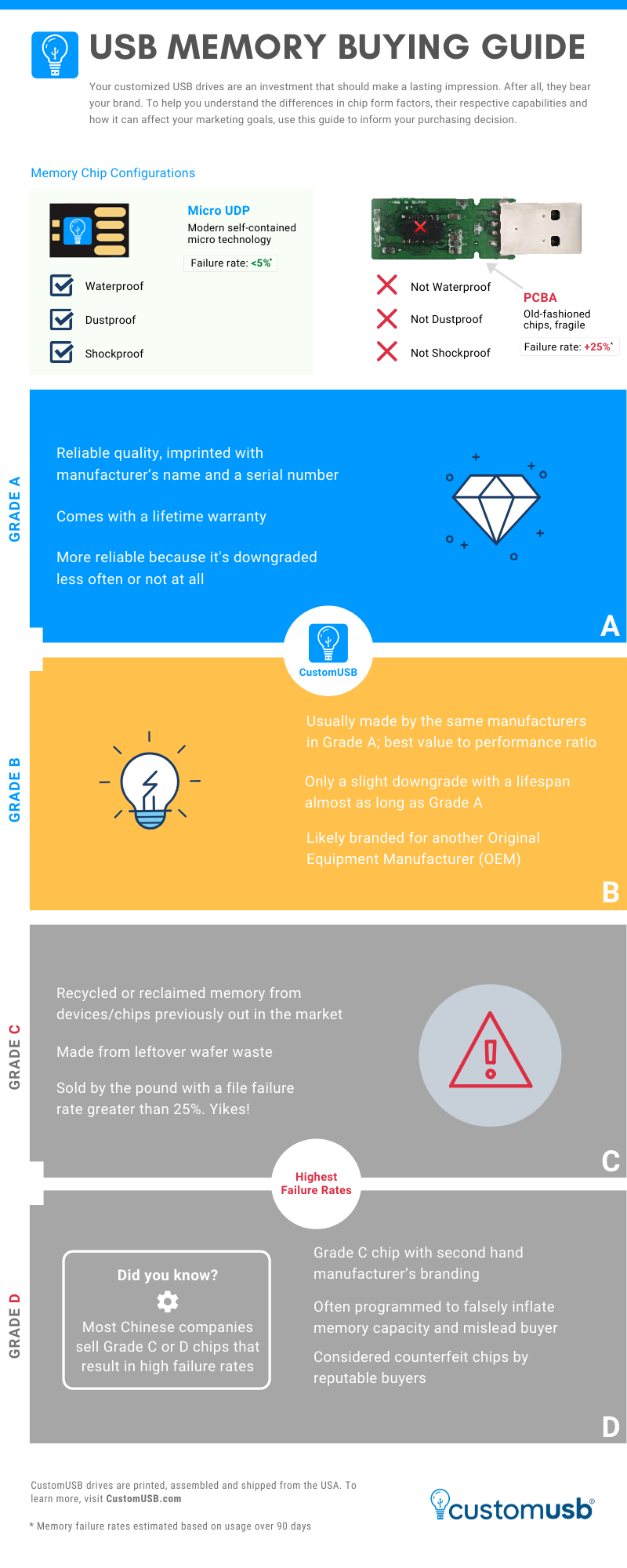

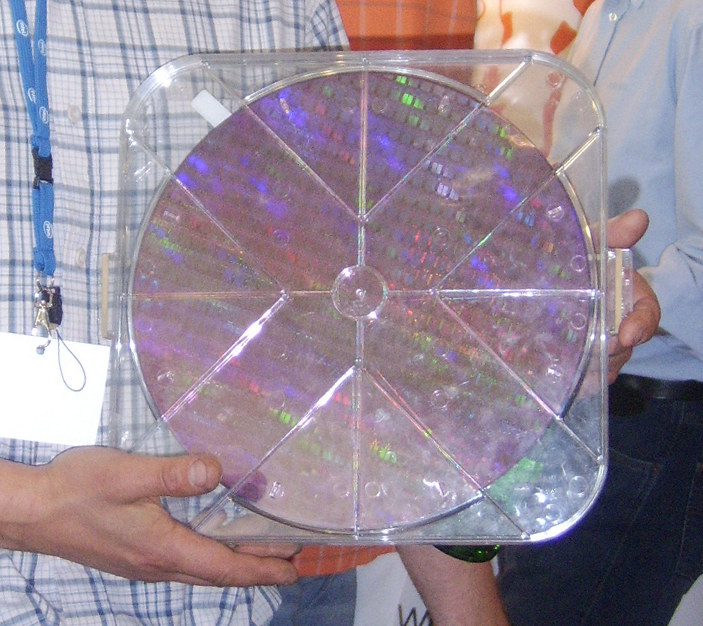

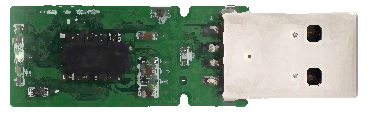

Understanding the technical components of any device can be challenging. To simplify your research, check out our handy buying guide to learn more about chip configurations and how it affects their overall performance. Promotional USB drives should leave a lasting impression, but with so many vendors and varying chip qualities available, how do you determine which product is worthy of bearing your name? Let’s look at the basics… All USB flash memory begins its journey as a single silicon wafer. The wafer is then etched with circuits and cut to chip size. Chips closer to the edges of the wafer are considered lower quality and are less likely to pass quality control inspections. As a way to distinguish quality standards, memory chips are categorized by grades A through D, with A representing the most reliable in terms of data retention and longevity. When evaluating flash memory, there are two important processes to understand, which have significant implications on quality and reliability. These are the processes of “downgrading†and “recycling.†When a chip is “downgraded,†it means the wafer did not pass the test for target max capacity, but did pass for a lower capacity. For example: 32GB Failed > 16GB Failed > 8GB Passed Technically speaking, downgrading is accomplished by programming the controller to ignore unreliable sectors of the wafer. This is a very effective method of salvaging large portions of the wafer, and often results in a reliable, yet low-capacity final product. As a rule, memory quality depends on the overall quality of the wafer and the degree to which the chip was downgraded. High-capacity chips are considered much more reliable than their low-capacity counterparts. Recycled memory means removing components from various electronics and chips already on the market and then mounting them to a printed circuit board. Recycling makes a chip highly susceptible to physical damage, and likely to have a high failure rate and low capacity. Micro UDP (USB Disk in Package) — Mini but mighty Micro UDPs pack high quality, compatibility and better performance into a petite design. They come in a range of capacities and choices for different dimensions including 11mm x 15mm, C11 .3mm x 15mm, all of which are protected by patents. With various MUDP adapters and housing available, MUDP is suitable for flexible and quick Flash Drive assembly and production. It’s an ideal solution for reliable and cost-effective flash memory. At a Glance: Micro UDP PCBA (Printed Circuit Board Assembly) — Green circuit board found in most electronics You’ve likely seen a green circuit board in many electronic devices. These are examples of Surface Mount Technology (SMT). PCB flash drives use SMT, where the board is heated and the components are sewed, glued or stapled in. PCBA chip makers often recycle memory from devices and chips already out in the market, resulting in a lower memory classification, lower capacity and a high failure rate of 30-40%. Most Chinese companies are known to sell highly unreliable Grade C or D chips. Of course, just because a flash drive contains a PCBA chip, doesn’t necessarily mean it’s going to fail. PCBA is suitable for certain applications. At a Glance: PCBA CustomUSB flash drives use factory-new MUDP chips, while many of our competitors use recycled PCBA memory do drive down costs (and quality). MUDP chips cannot be recycled. We encourage our clients to purchase higher capacities (4GB or higher) — because anything lower is likely to have a high failure rate. Your promotional items are a reflection of your brand. Be unforgettable and gift customers with noteworthy products. Still have questions about chip configurations and grades? Contact us today. Shopping Ortote Ordrawstring Bag Shopping Bags,Large Shopping Bag,Reisenthel Shopping Bag,Drawstring Bag Ningbo Fineweather International Trade Co., Ltd. , https://www.fwsbag.com

Keep reading to learn more…

What does “downgrading†mean?

What does “recycling†mean?

Get to Know the Chips: Micro UDP vs. PCBA

The CustomUSB Difference